Here’s Why We Don’t Have Opposed-Piston Engines—at Least Not Yet

They’re more efficient in every way, and now Calstart and Achates Power want you to consider the OP.

- The opposed-piston engine has been around for over 100 years and is more efficient in almost every way.

- The engine has no traditional valves, cams, or camshafts, and no head, so it’s simpler and cheaper to manufacture, assemble and operate.

- An Achates Power test engine will be running this summer in a Peterbilt 579. Another version—a 1000-hp engine for a combat vehicle—will be in series production by Cummins in 2024 for the U.S. Army.

Why does just about every motor vehicle in the world have a four-stroke Otto-cycle internal combustion engine? Surely after more than 100 years of the automobile someone must have thought of something better?

Well, they did, and almost from the start. No, I am not talking about the Wankel, though you have to give Mazda credit for sticking with that one as long as it did. And no, I’m not talking about the radial, the gas turbine, or steam. I’m talking about the opposed-piston engine.

Opposed-piston engines have been around since the late-19th century, so the idea isn’t new. In that time they’ve been placed in heavy-duty conveyances like trains, tanks, ships, and submarines. Their advantage early on was range. An airplane in the 1930s flew 6,000 miles with an opposed-piston engine without refueling. Submarines appreciated range, too. As did trains. You could go farther with the fuel you could carry using an OP engine.

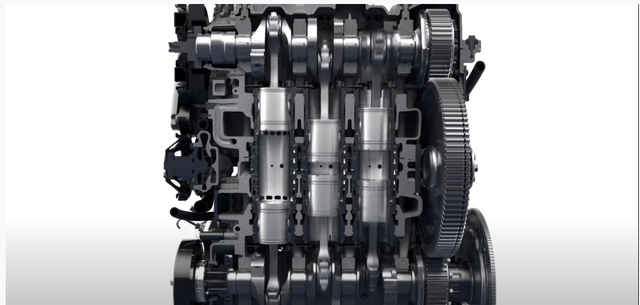

Here’s how an opposed-piston engine works: Two pistons share a common cylinder, each with its own crankshaft and con rod. The pistons move toward one another and (almost) meet at top dead center. As the pistons get closest to each other (or maybe just before) at the top of each stroke, diesel fuel is injected into the cylinder and combustion occurs. Since the engine we’re talking about here is a diesel, no spark plug is required. Then, bang, you get combustion, which pushes the pistons apart. Potential energy has been converted to work.

The two crankshafts, one on each end of the engine, are joined by a set of gears, from which power is sent to the wheels (or the propeller or whatever you’re powering).

The engine has no traditional valves, cams, or camshafts, and no head, so it’s simpler and cheaper to manufacture, assemble and operate. The heat of combustion doesn’t go to a cylinder head, it goes to the opposing piston, which is, again, more efficient.

I learned all of this during a webinar put on by Calstart, a consortium of 280 companies aiming to make cleaner air through more efficient transportation. The webinar covered medium- and heavy-duty trucks, and Calstart was encouraging companies to consider the opposed-piston engine for their trucks.

The company developing the engine is called Achates Power, in San Diego. It was founded by theoretical physicist Dr. James Lemke (1929-2019). Lemke developed all kinds of things over a long and productive career, including magnetic recording heads for broadcast TV tape recorders. If you ever watched TV in the years between live programming and the digital age, you can thank Lemke. He has over 114 patents. He used to like to fly his twin-engine Beech Baron to Baja for weekend getaways. On one such weekend he brought a book on opposed-piston internal combustion engine theory.

“You know, light reading,” he joked in a company video.

He learned that while such engines had been put into use over the years, it had never been developed to its modern potential.

“It was clear when I discovered this engine that it would be possible, using modern techniques like computational fluid dynamics, to improve the performance of the engine well beyond what was possible when it was first developed.”

So he founded a company to do just that. Achates Power was founded in 2004 and began developing the opposed-piston engine. Achates Power is not a manufacturing company; that would be left to engine makers like Cummins, Caterpillar, and Navistar.

“Achates Power works with leading engine companies, licensing designs, development and test tools, software, and patents that enable engines for a range of applications that reduce CO2 and critical emissions and provide robust compliance in a cost-effective manner,” says the boilerplate on the Achates website.

The heavy-duty truck engine demonstrator shows that between 1990 and today, NOx has been reduced by 98% and particulate matter by 99%. The California Air Resources Board has an upcoming regulation that will take NOx down another 90% and PM another 50% by 2027 (for a total of 99.8% reduction in NOx between 1990 – 2027). The results presented at the webinar this week show that Achates can reduce NOx 96% compared to today’s standards (65% below the 2027 CA standard) and CO2 by 7% below today’s EPA standard.

“Importantly, this is all done with conventional underfloor aftertreatment systems and is likely to be the most cost effective and robust way to meet the new standards,” said Achates Power’s executive VP for business development Larry Fromm.

Lemke cited one example.

“We know of one retail outlet that has 7,200 trucks. Their fuel bill last year just for those trucks was $350 million. We can save them $70 million to $100 million a year just by converting to this engine.”

So why isn’t everyone converting to this engine?

“It was a hangover of two-stroke horror stories that prejudiced the knee-jerk reaction of many people,” Lemke said. “Two-stroke? No you can’t make it clean you can’t make it efficient.”

Fromm adds some more perspective.

“Up until very recently (due to work by us, like what you saw yesterday), nearly everyone believed that two-stroke engines could not meet modern on-highway emissions standards,” Fromm said. “This is because the two-stroke cycle is very complicated—the gas exchange and combustion operate in one continuous event. You have to optimize the system as a whole. Before supercomputers and sophisticated chemically reactive computational fluid dynamics, optimization was done by intuition and trial and error. As a result, all two-stroke engines were dropped from regulated markets.”

“We are putting together a group of organizations to move the heavy-duty opposed-piston engine along the path to commercialization, with a goal to have engines available in 2027,” said Fromm. “I’ll note that another version of this engine—a 1000 hp engine for combat vehicle—will be in series production by Cummins in 2024 for the U.S. Army.”

Is the opposed-piston engine the Next Big Thing? Or is it just another one of a zillion engines other guys thought up 100 years ago that never went anywhere? Have a look at the Douglas-Self link here. It shows 115 engines, from the Bakewell Wingfoot to the Jasper Explosive Motor, that someone at some time thought would be the Next Big Thing.

I myself would selfishly encourage Porsche to replace its current flat six with an opposed-piston engine in a six-piston flat-three configuration. Or maybe Subaru should use one to make a FrankenSoob. I’m available for product planning and engineering consulting any time.