Achates 10.6 L opposed-piston diesel engine—status update

25 March 2021

Achates Power has been developing a 10.6 L opposed-piston (OP) 2-stroke cycle diesel engine, targeting Class 8 heavy-duty truck applications. In December, the company announced that the 3-cylinder, 300 kW OP engine achieved NOx emissions of 0.02 g/bhp-hr, which would meet the California 2027 emission requirements over the FTP cycle. Earlier this month, Achates Power also announced it will commence the development of two- and four-cylinder opposed-piston engine variants for Class 3-6 medium-duty applications. This project, supported by a $5 million grant from the US Department of Energy, will be conducted in cooperation with Isuzu, Clemson University and the University of Wisconsin-Madison.

In a follow up to these announcements, Achates Power provided additional details and some more recent results from the ongoing development work on the 10.6 L OP engine.

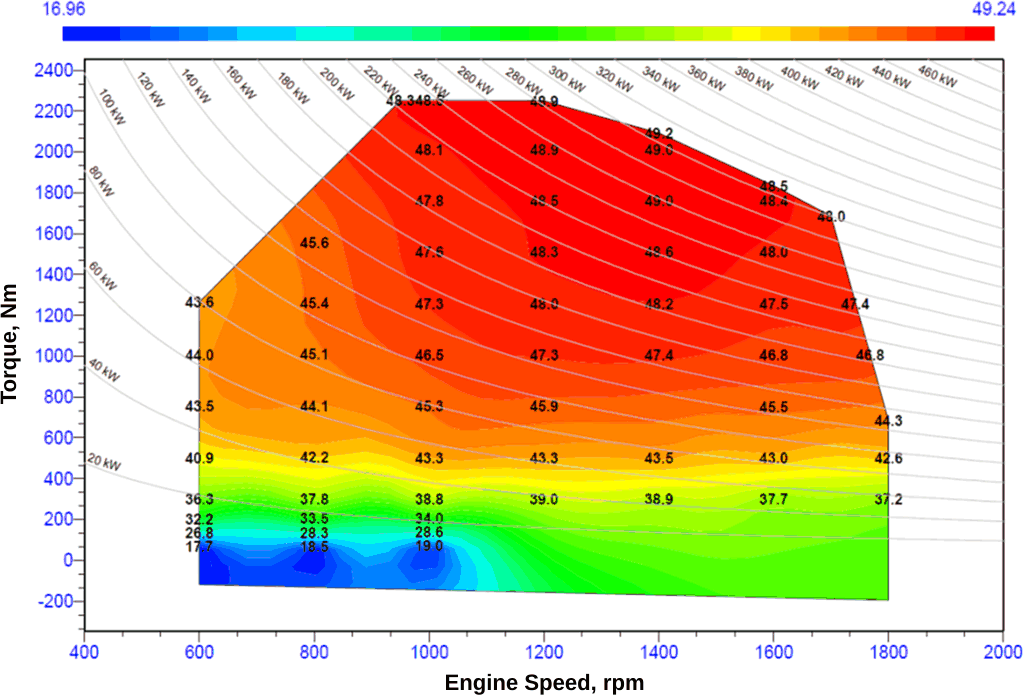

One of the advantages of the opposed piston architecture is a low surface area to volume ratio of the combustion chamber, which results in lower heat losses and higher brake thermal efficiency (BTE). In the 10.6 L OP engine, the maximum BTE is approaching an impressive 50%, Figure 1. This translates to low CO2 emissions—according to the most recent results, the engine produced 415 g/bhp-hr CO2 (RMC-SET cycle), as compared to the 2027 CO2 emission standard of 432 g/bhp-hr.

High efficiency mode

Achates Power promotes their 10.6 L OP engine as an efficient approach for meeting the 2024/2027 California Low NOx emission standards, which focus on emission reductions during low engine load operation such as in slow urban driving. This, in turn, will require efficient thermal management strategies to support fast catalyst light-off after cold start and during low load operation. Achates developed two calibrations for the 10.6 L engine: a high efficiency calibration, and a catalyst light-off calibration, with exhaust gas temperatures in excess of ~400°C over large areas of the engine map. The opposed piston architecture, where the engine charge is supplied by a supercharger/turbocharger rather than by engine pumping work, provides more flexibility in the air-to-fuel ratio control and exhaust temperature management. In contrast, 4-stroke diesel engines are expected to require such thermal management strategies as cylinder deactivation to meet the low NOx emission standards.

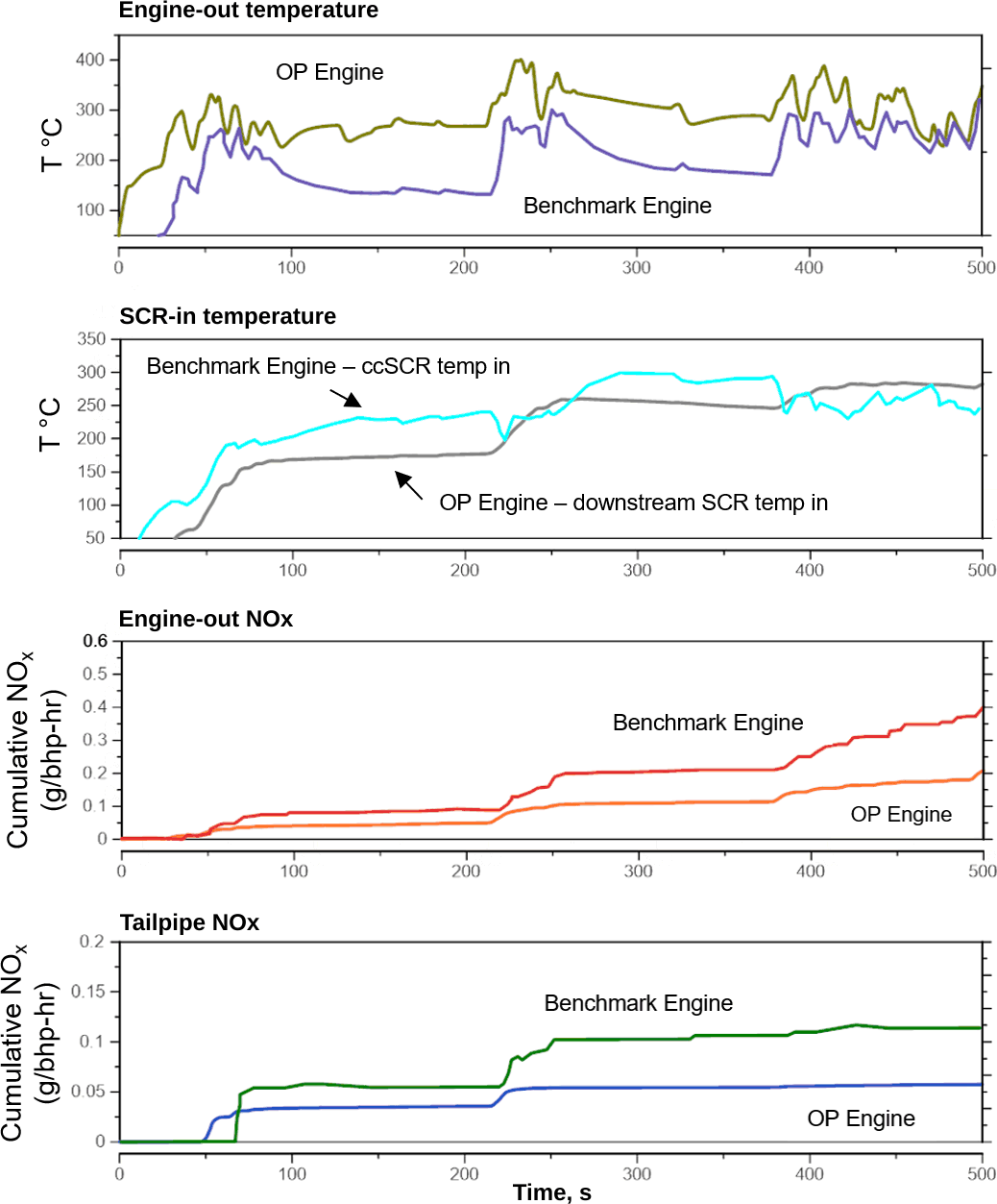

Figure 2 shows the exhaust gas temperatures and NOx emissions (cold start FTP) from the OP 10.6 L engine compared to a benchmark conventional engine. The benchmark engine is a 12.7 L 4-stroke cycle diesel concept for meeting the CARB low NOx emission standards, developed by the AVL [5081]. The aftertreatment system in the AVL concept engine includes an electrically heated catalyst (EHC) and a close-coupled SCR catalyst (ccSCR, V/Cu-Z), followed by underfloor DOC/DPF and SCR (V/Cu-Z)/ASC catalysts.

The Achates OP engine utilizes a conventional underfloor system, including a DOC + SCR-on-filter + SCR + ASC (i.e., without a ccSCR or EHC). In addition, Achates simulation showed that a standard MY 2021 system, including a DOC/DPF + SCR (Fe/Cu-Z)/ASC, would yield similar emission performance.

OP engine data from tests at Achates Power (San Diego, CA) and Aramco Services (Novi, MI). Benchmark engine data after AVL [5081]

The Achates 10.6 L OP engine produced 0.016 g/bhp-hr NOx over the composite FTP. Additionally, a simulation with a newer version of the 10.6 L OP engine with the MY 2021 aftertreatment system yielded NOx emissions of just 0.007 g/bhp-hr on the same test cycle. The benchmark engine in Figure 2 produced 0.018 g/bhp-hr of NOx, and experienced a 1% fuel consumption penalty due to the power consumption by the EHC.

Achates Power feels confident that the catalyst light-off calibration will allow the OP engine to also meet the applicable NOx emission limits over the low load (LLC) test cycle. In addition, the high temperature calibration may enable DPF regeneration without exhaust fuel injection, thus avoiding the related injection hardware.