Achates Power has developed a radically improved two-stroke opposed-piston internal combustion engine that increases fuel efficiency and reduces greenhouse gas emissions. Ansys simulation tools help the company to shorten design iteration time, minimize hardware prototypes and reduce the development time of new engines by approximately one year.

“Intensive use of Ansys simulation tools has enabled Achates Power to rapidly eliminate failure modes by iterating designs in days as opposed to months”

The new engine from Achates Power, Inc., is approximately 50 percent more fuel-efficient than conventional gasoline engines and 30 percent more fuel-efficient than diesel engines in combined city and highway drive cycles. This improvement was accomplished by eliminating the cylinder head in an opposed-piston configuration, which reduces the surface area of the combustion chamber relative to its volume, and therefore decreases heat transfer and heat rejection, the waste heat transferred to the coolant and metal. When less heat is wasted through the cooling systems, more fuel energy is available for useful work. Decreasing heat transfer to the coolant also makes it possible to shrink the cooling system and radiator size, reducing the overall system weight and cost.

The new engine from Achates Power, Inc., is approximately 50 percent more fuel-efficient than conventional gasoline engines and 30 percent more fuel-efficient than diesel engines in combined city and highway drive cycles. This improvement was accomplished by eliminating the cylinder head in an opposed-piston configuration, which reduces the surface area of the combustion chamber relative to its volume, and therefore decreases heat transfer and heat rejection, the waste heat transferred to the coolant and metal. When less heat is wasted through the cooling systems, more fuel energy is available for useful work. Decreasing heat transfer to the coolant also makes it possible to shrink the cooling system and radiator size, reducing the overall system weight and cost.

Because the engine has no cylinder head, the piston and cylinder liner must absorb a larger proportion of the heat generated by combustion, which is quite an engineering challenge. Achates Power engineers address this and other design challenges with Ansys simulation tools for computational fluid dynamics (CFD), conjugate heat transfer (CHT) and structural/thermal simulation to identify failure modes early in the design phase and fix potential issues well in advance of building and testing physical prototypes.

A COMMON PLATFORM SHORTENS DEVELOPMENT TIME

Ansys simulation tools provide Achates Power engineers with a common platform that has many options for solving multiphysics problems and exploring alternative designs. The design process starts with identifying all failure modes of concern. Engineers develop a computer-aided engineering (CAE) model so they can modify and evaluate designs virtually to shorten development time. Many analysis procedures used at Achates Power are automated with Ansys Workbench templates, reducing the time required for model setup and ensuring the use of consistent procedures and assumptions. Engineers perform real-time measurement of engine operating parameters such as temperature, pressure and flow at various conditions, and feed the data back into the analysis models to anchor them to real-life conditions. The team evaluates the simulation results and test data to locate the “cliff” — the point at which failure occurs. By iterating the design in the simulation environment, engineers can understand how design parameters affect key failure modes and move the design as far as possible from the cliff. Wherever possible they confirm the robustness of the design with accelerated lifetime testing.

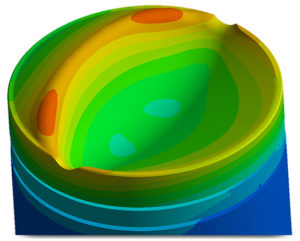

Hot spots predicted by advanced thermal modeling on the crown of the piston are addressed by changing the combustion parameters and bowl shape.

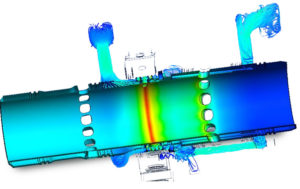

Conjugate heat transfer simulation results for the cylinder show high temperatures at the injector plane in the center of the cylinder axis.

CYLINDER LINER THERMAL–MECHANICAL SIMULATION

To manage the heat in the cylinder liner, Achates Power engineers first employ Ansys CFD to simulate the cooling channels so they can optimize flow rates, flow distribution and fluid velocity. They perform a 3D gas-side Ansys CFD simulation to determine wall heat transfer coefficients (HTCs) at a particular bulk temperature. Then another CFD simulation is done to calculate wall HTCs due to other heat sources, such as land gap heat. Similarly, ringfriction and piston-skirt–friction heat flux numbers calculated using a different tool are converted to equivalent HTCs. The cycle-averaged wall HTCs obtained from the gas-side CFD simulation and friction model are then used in the fluid–solid CHT simulation model to calculate metal temperatures. These metal temperatures and gas pressure conditions are applied to an Ansys Mechanical thermal–structural FEA model that calculates stresses and distortion in the cylinder liner. The stress numbers from the Ansys Mechanical model are then fed into the fatigue code to estimate the fatigue life of a liner. Achates Power has significantly improved the thermal model fidelity of the liner by identifying all possible heat sources and correlating the CHT model to the measured data. This simulation process has enabled Achates Power engineers to predict realistic temperatures on the liner surface and iterate the design to eliminate liner failure modes, such as ring/bore scuff, liner cracking and excessive bore distortion.

PISTON THERMAL–MECHANICAL SIMULATION

In opposed-piston engines, management of heat transfer into and out of the piston is critically important to keep pistons hot enough to maximize the brake thermal efficiency (BTE) but at the same time providing sufficient cooling to make pistons durable. Excessively high temperatures on the piston crown and under the crown can lead to several different failure modes, including crown oxidation, piston cracking and oil coking. To that end, predicting piston temperatures early in the design stage without actual test data is very important. Achates Power engineers perform transient simulation of open and closed cycles using a special combustion code to determine spatially resolved time-average heat flux distribution on the piston crown. The heat flux numbers from the combustion model are then mapped into an Ansys Mechanical steady-state thermal model that predicts the piston crown temperatures. In the advanced piston thermal modeling process, Achates Power engineers also run an undercrown oil flow CFD simulation to determine the gallery fill ratio and estimate HTCs. The entire simulation process between combustion CFD and Ansys thermal modeling is iterated several times until the desired metal temperature convergence is achieved. The flexibility of Ansys Workbench simplifies the process of integrating third-party tools into the analysis workflow. The piston metal temperatures obtained from the iterative thermal simulation are then mapped into an Ansys Mechanical thermal–structural model to calculate stress and deformation due to thermal and gas pressure loads. The stress data from the thermal– structural model is then fed into the fatigue code to calculate the piston fatigue life.

Piston temperatures as predicted by advanced thermal modeling correlate well with thermocouple measurements.

Using simulation to predict piston temperatures of individual design points and iterating the design to improve the temperature distribution, Achates Power engineers address piston failure modes in the early stages of the design process. As a result, they have significantly reduced the power cylinder development time by decreasing hardware iterations and also significantly improved durability of their engines in the past four years.

Design is an iterative and evolutionary process that requires finding a balance among many factors such as functional specifications, efficiency, durability, noise-vibration-harshness, mass and cost. Achates Power engineers continuously improve the modeling process by stretching the limits of the analysis tools to explore uncharted territories and capture real-world operating conditions. Intensive use of Ansys simulation tools has enabled Achates Power to rapidly eliminate failure modes by iterating designs in days as opposed to the months that would be required if they were using a traditional design process primarily based on physical prototypes. As a result, Achates Power now completely designs and develops new engines in one and a half years compared to three years with the traditional process.

“The new engine from Achates Power, Inc., is approximately 50 percent more fuel-efficient than conventional gasoline engines.”

Originally posted by Dnyanesh Sapkal on Ansys (July 16, 2018) (View Original Article)