Earlier this summer we told you about Achates Power’s efforts to use advanced technology to revive a novel World War II “opposed-piston” engine design for automotive use.

This week, that vision got an official vote of confidence from your very own government when Achates announced the U.S. Department of Energy’s Advanced Research Projects Agency – Energy (ARPA-E) awarded the company $9 million to help fund development of a 3-liter, 3-cylinder version of the advanced engine that would be suitable for today’s popular crossover vehicles and pickup trucks – but potentially make them demonstrably more fuel-efficient. This in addition to the $100 million or so Achates has garnered in private investment.

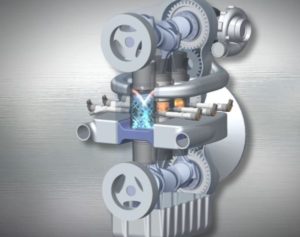

Achates opposed-piston engine design uses two pistons per cylinder and power-dense two-stroke operation to yield potentially large fuel-economy gains, and a new federally funded effort to adapt the engine to another advanced technology could deliver yet more efficiency. (Courtesy Achates Power)

The new, three-year federal ARPE-E funding seeks to advance the Achates engine’s already promising power-to-efficiency ratio by bringing in partners Argonne National Laboratory and automotive mega-supplier Delphi to apply gasoline compression-ignition technology to the engine’s existing design.

The idea is use gasoline but have the engine burn it as does a diesel, igniting the fuel not with spark plugs but with high pressure and temperature. The potential payoff is the improved efficiency of a diesel without the troublesome emissions that diesels generate – the emissions that currently have Volkswagen in hot water around the globe.

The idea of gasoline engines operating without spark plugs isn’t necessarily new – General Motors, for one, in the late 2000s revealed its earnest development effort to reap the theoretical benefits of sparkless gasoline engines in a program it called Homogenous Charge Compression Ignition, or HCCI (in fact, GM generated the wonderful video below that demonstrates how the technology works). And Argonne, one of Achates’ new partners, says it has been working on the compression-ignition gasoline engines for a decade.

The partners are convinced the alliance of Achates’ engine design, Argonne’s laboratory and complex computational engineering expertise and Delphi’s extensive history of fuel-injection development for production cars is the trifecta that can make the radical opposed-piston engine a viable new choice for everyday cars. Totally new or different engine designs are the absolute unicorns of the auto industry – they virtually never happen because today’s familiar. gasoline and diesel engines have been refined for more than a century.

But the auto industry’s drive to get to a new level of vehicle efficiency – combined with the enabling factor of increasingly sophisticated electronic controls – means the time just might be right for the first genuinely different automotive engine since the Wankel (rotary) first saw the light of day in the mid-1960s.

“Vehicle manufacturers are struggling to find cost effective ways to improve fuel efficiency by just a few percent points, but this combination (of Achates’ engine design and gasoline compression ignition technology) has the potential to dramatically exceed that number and be a major advance for the industry,” said Dan Hancock, president, DMH Strategic Consulting and retired vice president of General Motors Powertrain Global Engineering, in a statement. “Combining two very clean, very efficient, and cost effective technologies may well yield a new paradigm in engine design that could help satisfy the challenges of ground mobility for decades.”

Originally posted by Bill Visnic on Forbes (December 4, 2015) (View Original Article)