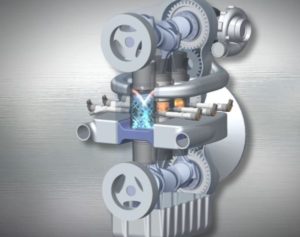

Internal view of Achates opposed-piston engine. (Illustration: Achates)

In a case of an old idea gaining new legs, Achates Power says it expects the first commercial use of its unique two-stroke, opposed-piston design to occur by 2020, following an initial in-vehicle demonstration in early 2018. It’s based on a design that’s well over 100 years old.

Achates, aiming to power both heavy-duty trucking and passenger vehicles, won’t say which will be the first to hit the streets using its technology, but much of the company’s development work so far appears tilted toward diesel truck engines.

Commercial trucking is the sweet spot of the market for Achates, chief executive David Johnson, a former Navistar executive, told Trucks.com during a recent tour of the company’s facilities in San Diego.

Truck operators are extremely fuel conscious and the Achates’ opposed-piston, or OP, engine can deliver up to 30-percent better fuel economy than existing internal combustion engines, he said. While the engine also improves on emissions, Johnson does not consider that a major selling point.

The trucking industry does care about emissions, but is “laser-focused on simultaneously increasing fuel economy” and reducing other costs, said Michael Held, an automotive industry analyst at the global consulting firm AlixPartners.

“Trucking companies will line up” to buy a new type of engine if the manufacturer can successfully validate its savings and reliability and durability claims, Held said.

Achates test lab. (Photo: Achates)

Achates’ diesel design can achieve the 55 percent engine efficiency goal – also called brake thermal efficiency, or BTE – of the five-year, $160-milliion SuperTruck II development program without the use of expensive add-on technologies, said Fabien Redon, Achates’ vice president for technology development.

Unlike two-stroke engines of old, the Achates design eliminates the need to mix oil or other lubricants with the fuel, delivering far cleaner emissions, said Redon, a former Detroit Diesel and General Motors diesel development engineer.

In heavy-duty diesel applications, Redon told Trucks.com, the Achates design results in a 50 percent to 90 percent reduction in NOx emissions, a smog- and ozone-causing product of fuel combustion.

And while most alternatives to conventional internal combustion engines are more costly, dampening trucking operators’ enthusiasm, the Achates design results in an engine that costs about 10 percent less than a conventional model, said Redon.

The Achates engine is based on the Atkinson-cycle engine developed by James Atkinson in 1882. He built three versions of the design that featured a short compression stroke and a longer expansion stroke, which were meant to provide efficiency at the expense of power density. The first application was called the “differential engine” and used opposed-pistons.

The Achates OP design places two pistons in a single cylinder, each connected to its own crankshaft. The design eliminates cylinder heads and valve trains. Slashing the number of moving parts cuts costs and significantly reduces heat losses and friction in the operating engine.

The engine is built using many of the same components and manufacturing techniques as a conventional internal combustion engine. That means mechanics don’t need significant retraining to work on it and manufacturers won’t need to do as much re-tooling to build it, said Bill Van Amburg, senior vice president and head of trucking programs for CalStart, a Pasadena-based consortium devoted to developing and promoting clean transportation technologies.

The Achates engine “can represent the replacement and future life of internal combustion,” Van Amburg said.

Achates’ engines run from a small, twin-cylinder (four pistons) 1.8-liter gasoline model suitable for passenger cars and small crossover SUVs to a 9.8-liter, three-cylinder (six pistons) diesel Class 8 engine rated at 450 horsepower and 1,550 pound-feet of torque.

The engines can work with electric motors in hybrid cars and trucks, serve as range extending generators for electric vehicles and be scaled larger or smaller than current designs, Johnson said. They also can be configured to work with various biofuels and natural gas, he said.

Cutaway of Achates engine. (Ilustration: Achates)

San Diego-based Achates, founded in 2004 by James Lemke, a physicist and self-described serial entrepreneur, is working with a dozen clients in the commercial and passenger vehicle segments. They represent about half of the world’s production of vehicle engines, Johnson said.

The company isn’t a manufacturer, but a developer that provides engineering and development services to its clients, customizing its engine design for their needs.

While the identities of most Achates clients are confidential, the company has announced a partnership with truck-engine builder Cummins Inc. on a military combat vehicle engine program and is working with automotive parts, components and services supplier Delphi Inc. and the Argonne National Lab on development of a light-duty pickup truck engine.

The company is not yet making profits, but revenue from its engineering services had doubled in the past few years to “about $20 million” for 2016, Johnson said.

The company has attracted more than $150 million in investment, said Johnson, and has grown to about 100 employees. Achates’ main facility is a four-building complex in a modest industrial park in San Diego and it recently opened a small engineering and marketing office in Farmington Hills, Mich.

Originally posted by John O’Dell on Trucks.com (December 30, 2016) (View Original Article)